Constantly Innovation Make 8000+ Businesses Trust Hubo Expertise

Innovation Technologies

Magnetic Heated System On Lenses

Magnetic heated system was applied to ensure the quickly interchange of lenses in seconds , besides, this system which quick demisting of heating, and its anti-fog fuction can last for super-long 6 hours.

Magnetic Removable Foam

Hubo's ski goggles feature a cutting-edge magnetic suction system that allows your customers to easily replace the sponge material, ensuring maximum comfort and hygiene on the slopes.

Interchangeable System in Straps

In Hubo, we offer unparalleled flexibility with interchangeable straps that can be swapped out using slide buckles or other methods, ensuring maximum comfort and a personalized fit.

Application of Renewable Materials

Bio-Based Materials On Frames

Hubo keeps an eye on the industry and listens to customer feedback, we have started using bio-based materials that do not contain harmful chemicals and are more in line with health and safety standards, while being able to provide a healthier skiing experience.

- Renewability Testing: Assess the renewable nature of a material

- Physical Properties Testing: Evaluate the physical properties of a material, such as tensile strength, flexural strength, impact strength, hardness, etc.

- Chemical property tests: Evaluate the chemical properties of the material, such as chemical resistance, UV radiation resistance, etc.

- Ecotoxicity testing: Assesses the ecotoxicity of the material in the environment.

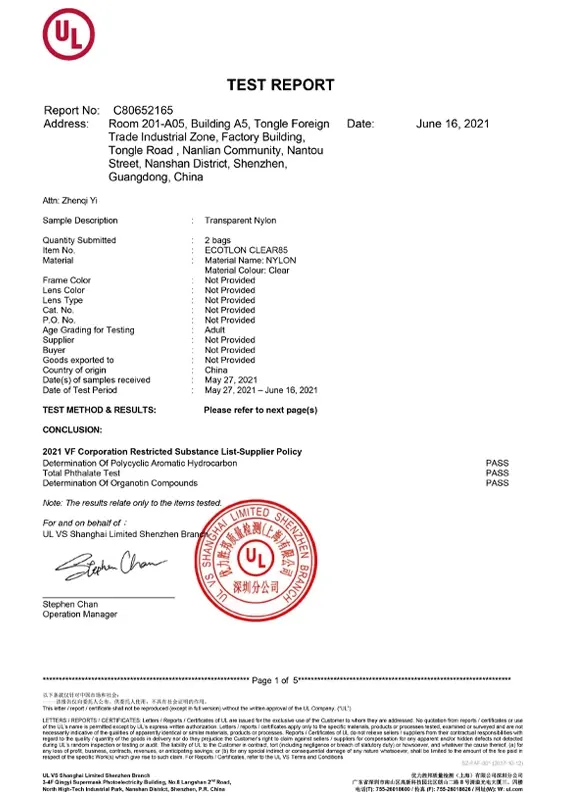

Recycled Nylon Lenses

Hubo uses recyclable nylon lenses that are environmentally friendly while taking full advantage of the other benefits of these lenses.

In addition to being very light and durable, recyclable nylon lenses are also highly transparent and have a low refractive index, providing users with clearer and more accurate vision and less susceptible to optical aberrations.

You can also customize them with various colors and mirror effects through dyeing or coating to meet the individual needs of different consumers.

Global Reporting Initiative

European Energy Certificate System

Renewable Straps

The straps used on our goggles are made from renewable materials and are GRS and ESTS certified. Making straps from renewable materials can add value to your brand, making your products more attractive and competitive. At the same time, renewable materials are usually relatively inexpensive. Using such materials can reduce the manufacturing cost of your products, thus bringing higher profitability and better financial performance to your company.

Fully Automated Equipments

Injection Molding Machine

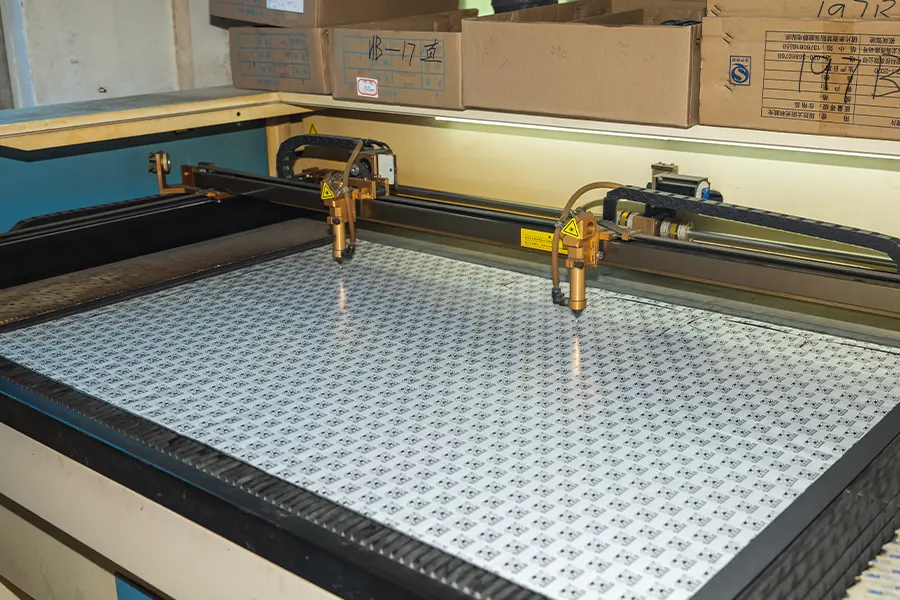

Fully Automatic Lens Cutting Machine

Laser Engraving Machine